Part 1: Breaking Free from the Status Quo

In the natural gas transmission industry, the shift from a periodic maintenance to a condition-based maintenance paradigm will be enabled by the wealth of data generated by today’s smart measurement stations, combined with real time analytical services like C-SMART that are efficient and low cost due to their cloud-based market delivery model. The technology and services are available and deployed. Everything is in place to enable change, but something is holding teams back from taking the necessary step to break free from the status quo.

The natural gas supply chain can’t hold back the change that is inevitable. The forces that are making condition based maintenance an imperative are building pressure as the measurement drivers to make use of the data and services become more acute. Ironically, resisting the paradigm shift under sustained capital discipline and cost containment compounds the impact on an organization’s bottom line in the face of technology and the data team’s already have that can actually help by shrinking O&M budgets, accelerating the shift to conditioned based maintenance. Drivers include:

- Investor demand for return on deployed IIoT

- The need for continued efficiency improvement through each boom-and-bust cycle caused by commodity price volatility

- Demand for climate action and Wall Street sentiment

- The “Big Crew Change” becoming a “Big Crew Drain”

Even more importantly, the maintenance, failure, error, and root causes data collected in real time from these measurement stations by early movers over the last ten years provides a comprehensive and compelling success story, driving total error down by 80% and increasing resolution time by 100 – 150%.

The natural gas industry has both motivation and a validated means to undertake the transition and reap the benefits. The next question to address is “How does the industry proceed stepwise through the transition?”

Process Definition

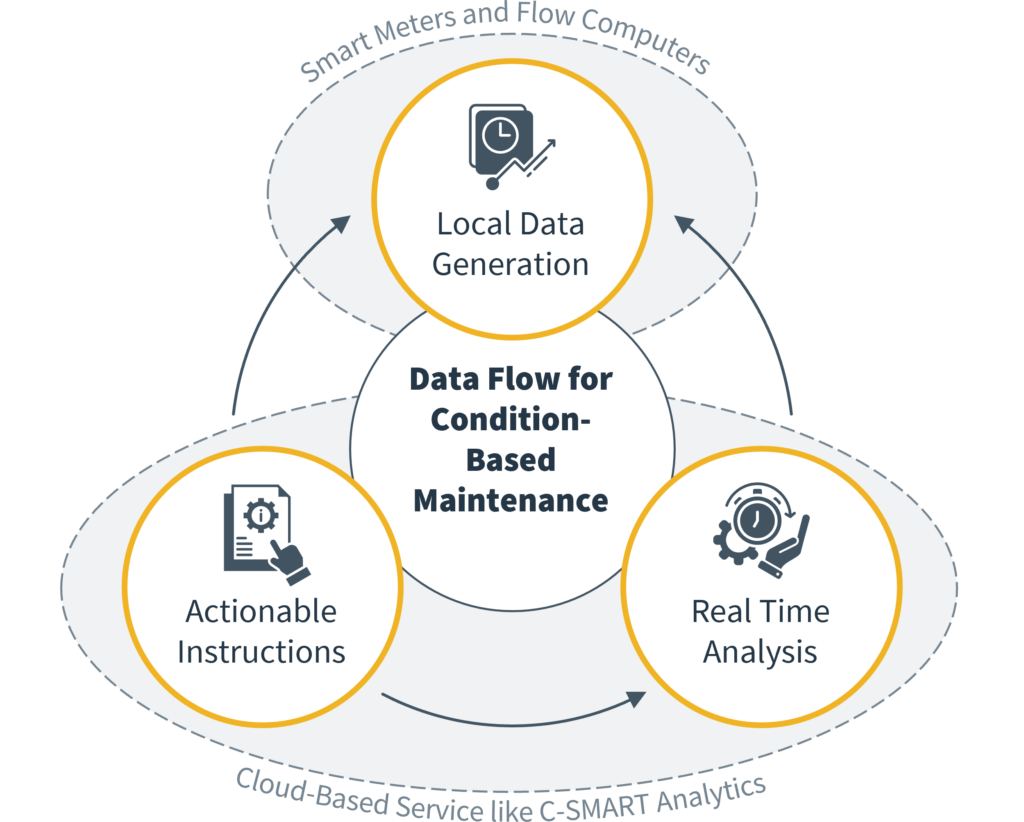

The figure below considers the total process and helps us determine the hurdles to a successful transition. Condition-based Maintenance requires continuous data from the smart devices, analysis of the data in real time, and actionable results communicated to teams to take action to resolve problems, as shown in Figure 1.

From 100,000 feet, the steps are complete in the midstream natural gas delivery chain – smart devices are measuring the gas to a large extent, and companies like C-SMART provide comprehensive real time analysis and actionable directions for technicians to resolve errors when they occur. So, what’s the challenge? A bottom-up, more detailed analysis of the process is required.

The next figure breaks down the process further to provide better resolution and identify the challenges for today’s natural gas gathering, transmission, and distribution companies.

Local Data Generation

There has been a successful industry-wide adoption of smart measurement devices, including ultrasonic meters, Coriolis meters, flow computers, and gas chromatographs. There are an estimated 100,000 smart flowmeters throughout the world today installed in natural gas measurement stations and generating diagnostic data, with the USA accounting for about 25% of the installed base. Local data generation is not a hurdle today for a large portion of the market, yet the data is stranded and vastly underutilized because of the volume, velocity, and variety (the very definition of a big data problem).

Lack of confidence in real results staring them in the face and the age old problem of waiting for someone else to be first – this is why most gas pipeline operators are standing still instead of taking a leap [of faith many argue] to conditioned based maintenance. Over the next few blogs in a series aimed at knocking the industry off the fence, you’ll learn how to take the next step, free the stranded data needed for the paradigm shift to conditioned based maintenance and close the automation loop by connecting AI recommended error resolutions with field tickets for even more operational and cost efficiency.